Back-To-Back Installation Of FAG Tapered Roller Bearings

2020-04-24 11:12 Author:admin Click:

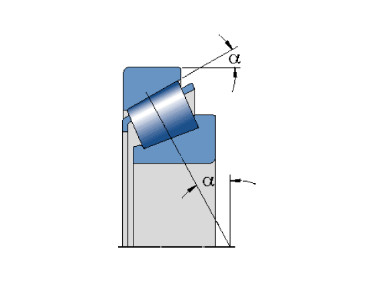

Single-row FAG tapered roller bearings have tapered inner and outer ring raceways. Tapered rollers are generally separated by stamped cages between the inner and outer raceways. This type of product can withstand combined radial and axial loads, and the bearing's ability to withstand axial loads is determined by the contact angle α. The greater the α, the higher the ability to withstand axial loads.

1. Installation site

Bearings should be installed in a clean, dry environment. Keep away from metal processing equipment or machinery and equipment that generates metal debris and dust. When it is necessary to install bearings in unprotected areas (this is often the case when installing very large bearings), measures must be taken to protect the bearings, installation locations and related parts from dust, dirt and moisture, such as wax paper, Plastic cloth or rags cover or wrap bearings, journals and other related parts.FAG tapered roller bearings FAG 33017

2. Preparation before installation and disassembly

Prepare all necessary parts, tools, equipment and materials before installation. Study the drawings or instructions carefully to determine the correct installation order of the different parts. Check the bearing box, shaft, seals and other parts of the bearing configuration to see if they are clean, especially where there may be residual holes such as screw holes, conduits or grooves. Check the dimensional and shape tolerances of all components in contact with the bearing.

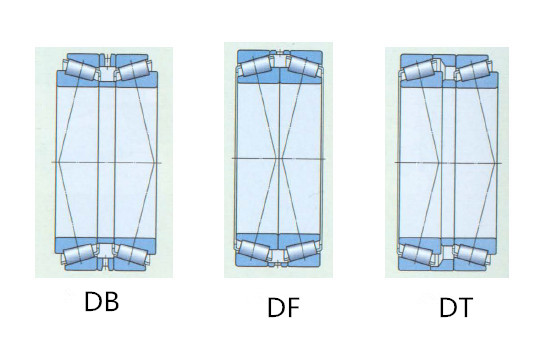

3. Single row two sets of bearings installed back to back

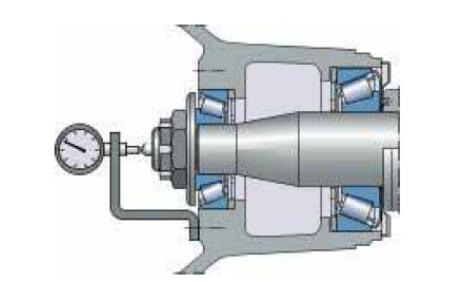

Single-row FAG tapered roller bearings are generally installed in pairs, you can install two outer rings with large end faces opposite to each other (DB), two outer ring with small end faces facing each other (DF), or one outer ring is small The end face is connected in series with another large end face of the outer ring (DT). During the back-to-back installation of the bearing, the outer inner components are subject to installation, disassembly, and re-installation. The fit between the bearing inner diameter and the shaft should be selected appropriately, and the correct and reasonable tools should be used to facilitate the installation and disassembly to ensure the shaft The rings, rollers and cages are not damaged.

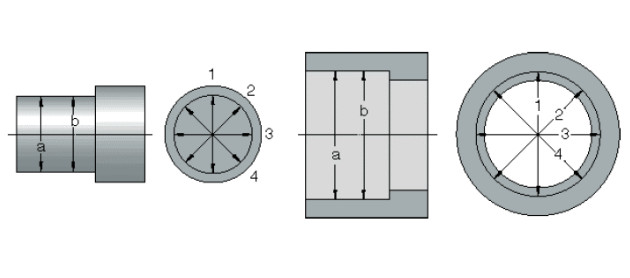

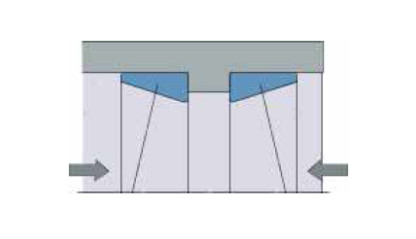

Install the outer ring of the bearing into the bearing housing hole as shown below. Generally, there is a gap between the outer diameter of the bearing and the hole of the bearing seat. It is easy to push the outer ring into the inner hole of the bearing.

Pay attention to the perpendicularity of the outer ring and the axle box, and ensure that the end face of the outer ring contacts the hole shoulder of the axle box after installation.

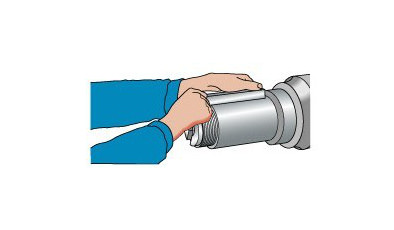

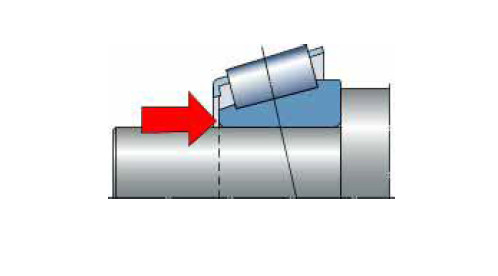

Use appropriate tools to install the bearing internal components on the journal (such as sleeve). Note that the pressure must not act on the roller or cage.

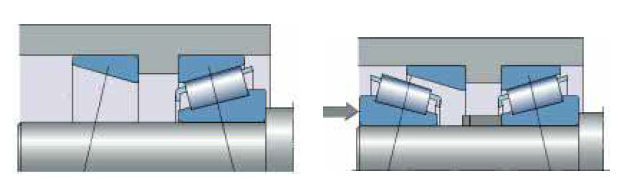

According to the axial clearance marked in the drawing, adjust the matched bearings as follows. Generally, the axial clearance can also be adjusted within the range of +0.02 to + 0.10mm.

◆ Use a wider spacer ring to make the axial clearance after preliminary adjustment slightly larger than the set value.

◆ According to the difference between the initial adjusted measured value and the set value, the width of the spacer ring to be reduced can be calculated to obtain the required axial clearance.

◆ Place the dial indicator on the shaft end, the shaft is pushed firmly to one of the shaft ends, turn the shaft a few times to ensure that the end face of the roller contacts the rib of the inner ring. Record the dial indicator reading. Push the shaft in the opposite direction in the same way and record the reading. The difference between the two sets of data is the measured axial clearance.

◆ The width of the spacer ring can be calculated by the following formula: width reduction = measured axial clearance-set value of axial clearance

◆ Remove the inner ring on the outer side and replace the spacer ring that fits the size.

ERIC Bearing Company has been focusing on the bearing industry for 10 years. We will stick to our heart and work hard to provide the best bearings for the world.Click here to buy FAG tapered roller bearings