Thrust Ball Bearing Characteristics.

For Thrust ball bearings,Eric Bearing Limited clarify as below:

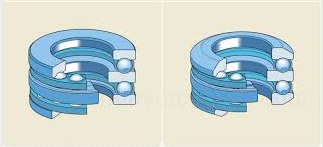

1. There are two types: one-way and two-way.

2. Thrust ball bearing can only bear axial load. One-way thrust bearing can only bear axial load of one direction, and two-way thrust bearing can withstand the alternating axial load of two directions.Need SKF 51100,click here

3. Thrust ball bearing can not limit axial or radial movement of box, its limit rotational speed is low, the unidirectional thrust bearing can restrict the shaft or the axial movement of one side of the box body, a two-way bearing can limit the shaft or housing in two of the axial direction of movement.

4. When using this kind of bearing, if the axis of the shaft and housing holes different heart, will cause premature bearing damage, in order to eliminate this kind of undesirable phenomenon, can be between casing hole and set aside in a living circle diameter 0.5 mm ~ l radial clearance.Also required supporting surface should be kept vertical shaft centerline and enclosure, in order to eliminate by the body bearing surface and the shaft centerline of vertical bearing center tilt, can be in a living circle of support on the mat with elastic lining, such as cloth, leather and oil resistant rubber MATS, etc.

5. The thrust ball bearing is in operation. Due to the function of inertial force, the steel ball and the raceway have to slide, which makes the temperature rise and the working surface is liable to be damaged.Therefore, in order to prevent the steel ball sliding between the raceway, the thrust ball bearing must be minimum axial force in the work.

6. In order to allow the installation error, either one-way or two-way, the spherical adjustable spherical seat cushion or spherical seat ring can be selected.

Below are some of our Single direction thrust ball bearings list for your reference:

|

Boundary dimensions |

Mass |

Bearing NO. |

||

|

(mm) |

(kg) |

|||

|

d |

D |

T |

|

SKF |

|

10 |

24 |

9 |

0.018 |

51100 |

|

10 |

26 |

11 |

0.029 |

51200 |

|

10 |

26 |

11.6 |

0.028 |

53200 |

|

12 |

26 |

9 |

0.021 |

51101 |

|

12 |

28 |

11 |

0.032 |

51201 |

|

12 |

28 |

11.4 |

0.03 |

53201 |

|

15 |

28 |

9 |

0.024 |

51102 |

|

15 |

32 |

12 |

0.043 |

51202 |

|

15 |

32 |

13.3 |

0.046 |

53202 |

|

17 |

30 |

9 |

0.024 |

51103 |

|

17 |

35 |

12 |

0.05 |

51203 |

|

17 |

35 |

13.2 |

0.052 |

53203 |

|

20 |

35 |

10 |

0.037 |

51104 |

|

20 |

40 |

14 |

0.082 |

51204 |

|

20 |

40 |

14.7 |

0.081 |

53204 |

|

25 |

42 |

11 |

0.055 |

51105 |

|

25 |

47 |

15 |

0.114 |

51205 |

|

25 |

47 |

16.7 |

0.121 |

53205 |

|

25 |

52 |

18 |

0.154 |

51305 |

|

25 |

52 |

19.8 |

0.203 |

53305 |