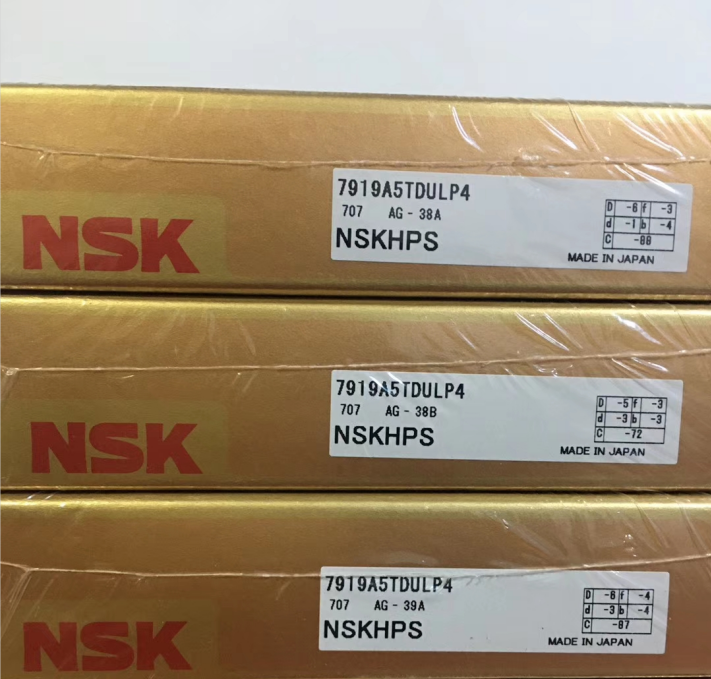

NSK precision bearings

1. The tolerance level of the bearing is determined according to the rotation accuracy requirement of the axial support.

Level 0: it is widely used in general bearing systems with rotating precision greater than 10 m.Such as the speed change mechanism of common machine tool, the speed change mechanism of feeding mechanism, automobile, tractor, ordinary motor, water pump and agricultural machinery, etc.

Level 6, 5, in the rotating accuracy in 5 to 10 microns or high speed precision bearing system, such as ordinary lathe used bearings (front support with 5 levels, support level 6) after the precision instruments, meters and precision instruments, meters, and the precision of the rotating mechanism.

Level 4,2: in the rotating precision of less than 5 microns or in ultra precision instruments with high speed, such as precision coordinate boring machine, precision grinding machine of the gear system, precision instruments, meters and high-speed cameras and other precision system.

2.For NSK precision bearings, it is different from ordinary bearings in raw material performance, size, rotation precision, bearing surface and other aspects.In the performance of raw materials, the performance of precision bearings is better;In terms of size, the requirement for size value is relatively low;In the rotation precision, higher requirements;For the bearing surface, including the surface shape and surface quality of the two aspects of the content, the precision bearing requirements are more stringent.For example:NSK 7919A5TDULP4 / NSK NN3020TBKRCC0P4,ETC. they both with P4 grade,with good performance